Polyurethane resin plays an important role in the development of composite materials. It is a key factor in achieving more economical and larger batch manufacturing of automotive composite parts (including electric vehicle battery covers and underbody protection, door frame reinforcement, and interior trim and panels). , Especially the sandwich structure. The Jubang Industrial team focuses on continuously improving the physical properties, productivity, total cost and compatibility of core materials and resin materials, which can provide automotive equipment manufacturers with advantages in lightweight, design freedom and simplified manufacturing.

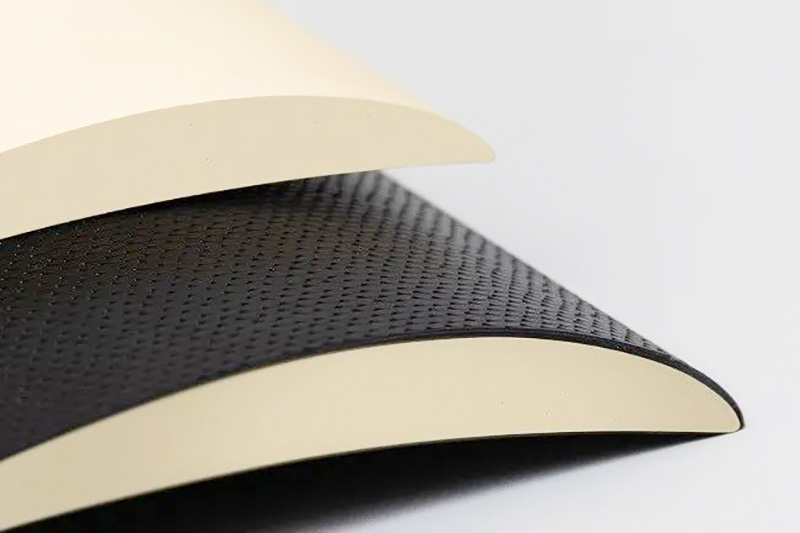

Injection molding on the core material, the penetration of the fiber-reinforced material by the fast-curing polyurethane resin provides rigidity, high strength and long-term durability for the lightweight composite sandwich design, including complex 3D parts with strict dimensional tolerances, realizing more automotive composite parts Key factors for low-cost and mass-manufacturing.

Polyurethane material combinations can be used to manufacture molded polyurethane core materials with complex shapes, with almost no size restrictions, achieving greater design freedom. The company stated that the foam core material made with its polyurethane material combination is a good foundation for the strength and life reliability of composite parts. The density and thickness can be changed, and it can be equipped with additional properties such as temperature and fire resistance. Compression resistance at high temperatures also means that the foam can resist resin pressure during the composite molding process, limiting resin penetration into the core material.